Rare earth magnets are renowned for their exceptional strength and wide range of applications in industries like electronics, automotive and medical technology. This guide provides an in-depth look at rare earth magnets, including key types like neodymium magnets, their unique properties, and practical uses. It also highlights the distinctions between rare earth magnets and neodymium magnets, helping you understand which is best suited for different applications.

Rare earth magnets are powerful permanent magnets known for their exceptional strength and resistance to demagnetization. What are rare earth magnets made from? They are primarily composed of alloys containing rare earth elements like neodymium, samarium, and dysprosium. These elements, though not truly rare, possess unique atomic structures that enable the creation of high magnetic anisotropy and energy density. The most common types are neodymium magnets (NdFeB) and samarium-cobalt magnets (SmCo). These magnets are manufactured through processes like sintering or bonding, which optimize their magnetic properties. Their strength and durability make them indispensable in various industrial and technological applications.

Rare earth magnets are primarily divided into two main types: neodymium magnets and samarium-cobalt magnets, with a third category being bonded rare earth magnets. Each type has unique properties tailored to specific uses and environments.

Cone-shaped rare earth magnets in Meank Magnets

Neodymium magnets, also known as NdFeB magnets, are composed of neodymium, iron, and boron. They are the strongest type of rare earth magnet, offering exceptional magnetic strength and a high energy-to-weight ratio. Although they are cost-effective and widely used, they are susceptible to corrosion and have limited resistance to high temperatures unless specially treated. To enhance their durability, coatings such as nickel or epoxy are often applied.

Samarium-cobalt magnets are made from an alloy of samarium and cobalt. While slightly less powerful than neodymium magnets, they excel in high-temperature environments, withstanding up to 350°C. Their natural resistance to corrosion eliminates the need for additional coatings, making them reliable in harsh or chemically corrosive conditions. Especially China SMCO magnets are preferred for applications demanding thermal stability and resistance to demagnetization.

Bonded rare earth magnets are manufactured by combining magnetic powders with a binding material, resulting in a flexible and lightweight product. While they have lower magnetic strength than sintered magnets, their ability to be molded into complex shapes makes them invaluable for precision devices or custom designs. Additionally, bonded magnets are resistant to chipping and corrosion.

As a professional manufacturer, we recommend selecting neodymium magnets for their unmatched strength in compact spaces, samarium-cobalt magnets for high-temperature or corrosive conditions, and bonded magnets for custom or intricate designs. Each type should be chosen based on environmental factors, strength requirements, and application-specific needs to ensure optimal performance.

| Property | Neodymium Magnets (NdFeB) | Samarium-Cobalt Magnets (SmCo) | Bonded Rare Earth Magnets |

| Composition | Neodymium, Iron, Boron | Samarium, Cobalt | Magnetic powder with a binding material |

| Magnetic Strength | The strongest rare earth magnets, high energy-to-weight ratio | Strong, but not as powerful as neodymium magnets | Lower magnetic strength compared to sintered magnets |

| Temperature Resistance | Up to 80°C (standard), up to 220°C (high-temperature grades) | Up to 350°C | Lower temperature resistance compared to sintered magnets |

| Corrosion Resistance | Prone to corrosion, needs coatings (nickel, epoxy) | Naturally corrosion-resistant, no coating required | Naturally resistant to corrosion, no coating needed |

| Cost | Relatively affordable | More expensive due to rare materials | Cost-effective, depends on bonding process |

| Applications | Electronics, motors, sensors, compact devices | High-temperature, high-reliability, aerospace, and military | Custom shapes, precision devices, lightweight applications |

| Durability | Can be brittle and prone to chipping or cracking | Highly durable, resistant to cracking and demagnetization | Durable, resistant to chipping and cracking, but lower strength |

| Shape Flexibility | Typically available in standard shapes (disks, blocks, etc.) | Limited shape options due to sintering process | Highly customizable shapes and sizes |

| Strength-to-Weight Ratio | Very high, ideal for compact, powerful applications | Good, but lower than neodymium magnets | Lower strength, more suited for low-weight applications |

| Manufacturer's Recommendation | Ideal for applications requiring maximum strength and compactness | Best for extreme temperatures and corrosive environments | Best for custom designs and applications requiring flexibility |

Rare earth magnets encompass a broad category of permanent magnets made out of rare earth elements. These magnets are known for their exceptional magnetic properties, such as high magnetic strength and resistance to demagnetization. They are used in a wide range of industries, from electronics and automotive to medical devices and renewable energy, thanks to their reliability and efficiency.

Bulk neodymium magnets are a specific type of rare earth magnet made primarily from an alloy of neodymium, iron, and boron (NdFeB). These magnets are considered the strongest type of permanent magnet available, offering the highest energy-to-weight ratio. Due to their impressive performance and relatively low cost, neodymium magnets are widely used across a variety of applications, including electronics, motors, and various small devices.

While all neodymium magnets are considered rare earth magnets, not all rare earth magnets are neodymium. The term "rare earth magnets" includes several other types which offer different properties like superior temperature resistance but with lower magnetic strength. Neodymium magnets stand out for their unmatched magnetic strength and are a more cost-effective option compared to other rare earth magnets.

| Feature | Rare Earth Magnets | Neodymium Magnets |

| Type | Broad category | Specific type within rare earth magnets |

| Strength | High magnetic strength | Strongest type of permanent magnet |

| Composition | Various rare earth elements | Neodymium, iron, and boron (NdFeB) |

| Applications | Wide range of applications | Diverse applications, especially in electronics and motors |

In essence, all neodymium magnets are rare earth magnets, but not all rare earth magnets are neodymium. Neodymium magnets are a specific type of rare earth magnet that offers exceptional magnetic properties and is widely used in various industries.

Neodymium magnets are widely used in electronics such as smartphones, tablets, and computers. Their strong magnetic properties enable compact components like speakers, microphones, and hard drives, allowing devices to be smaller and more efficient without sacrificing performance. These magnets are essential for the miniaturization of modern electronics, enhancing functionality in a reduced form factor.

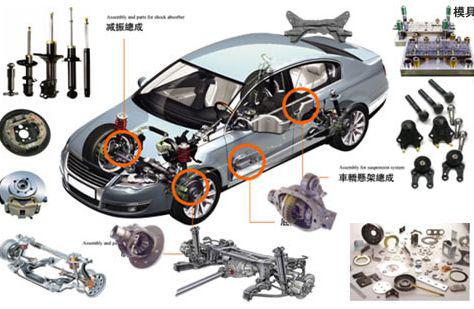

In electric vehicles (EVs) and industrial motors, rare earth magnets, particularly neodymium, improve motor efficiency. Their strong magnetic fields increase performance, reduce energy consumption, and help extend battery life. These magnets are crucial in powertrains and regenerative braking systems, contributing to smoother operation and better overall energy efficiency in electric and hybrid vehicles.

Rare earth magnets, especially neodymium, are vital in renewable energy systems like wind turbines. They help convert mechanical energy into electrical energy with high efficiency, using smaller, lighter motors that maximize power output. This efficiency supports sustainability efforts by improving energy generation in eco-friendly technologies like wind power, reducing reliance on traditional energy sources.

In medical technologies, rare earth magnets are key components in devices like MRI machines. Neodymium magnets generate strong magnetic fields needed for detailed imaging. Additionally, their compact size and power make them suitable for devices such as hearing aids, offering effective solutions in medical diagnostics and treatment while maintaining a lightweight design.

Rare earth magnets are used in magnetic fasteners and holding systems across industries like manufacturing and construction. Their powerful magnetic fields securely hold heavy components in place, such as doors, tools, and machinery parts. These magnets are ideal for applications requiring both strength and compact design, providing reliable solutions in industrial and everyday settings.

In maglev trains, rare earth magnets enable frictionless travel by levitating the train above the tracks. Neodymium magnets, in particular, are crucial due to their strong, stable magnetic fields, allowing for high-speed, efficient transportation. This technology reduces wear and tear, enhances speed, and improves energy efficiency, revolutionizing how we think about future transportation.

You can find out further information about the application of rare earth magnets in this article:

The Application Of Rare-Earth Permanent Magnets

1. Are rare earth magnets dangerous?

Yes, rare earth magnets can be dangerous if not handled properly. Their powerful magnetic force can pinch skin or fingers, potentially causing injuries. If two magnets snap together, they can shatter and create sharp fragments. Swallowing small rare earth magnets is extremely hazardous, especially for children, as they can attract each other across intestinal walls, leading to severe internal damage or even life-threatening injuries. Additionally, their strong magnetic fields can interfere with medical devices like pacemakers or damage sensitive electronics.

To minimize risks, handle them with care, keep them away from children and electronic devices, and store them in a safe, separated manner.

2. Can rare earth magnets lose their magnetism?

They are highly resistant to demagnetization but can lose magnetism under extreme heat or mechanical stress, depending on the type.

3. Are rare earth magnets recyclable?

Yes, they can be recycled, but the process is complex and not widely available. Recycling rare earth materials is an area of growing interest due to limited resources.

4. Are rare earth magnets waterproof?

No, they are not naturally waterproof. Neodymium magnets, in particular, can rust in moisture. Coatings like nickel, epoxy, or plastic can be applied to improve corrosion resistance.