Neodymium magnets, also known as NdFeB magnets, are commonly used commercial rare earth permanent magnets. Its main phase molecular formula is Nd2Fe14B, which has high magnetic energy product (the size of the magnetic energy stored by the magnet) and coercive force (the ability of the magnet to resist demagnetization), so it is called the "magnet king". Its electrical conductivity is about 0.6×106Siemens/m, so it has electrical conductivity.

Although the conductivity is not as good as that of ordinary conductive metals (the conductivity is more than an order of magnitude worse), it is a material with relatively high conductivity in permanent magnets.

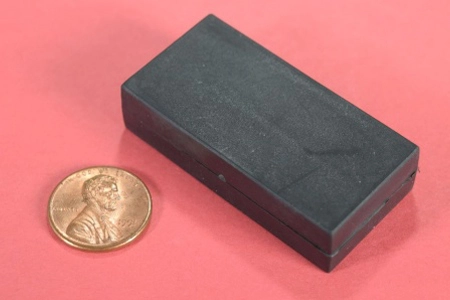

Neodymium magnets, like NdFeB cone magnets, have strong chemical activity and are easy to rust, so they are generally treated with surface coatings, and some surface coatings are also conductive metal materials, such as zinc plating, nickel plating, etc.

If a DC thin neodymium magnet is applied, a toroidal magnetic field will be created. In general, the current is small and has little effect on the magnetic field of the permanent magnet itself.

As a simple estimate, the current in the DC wire is 1 ampere hour, and the strength of the magnetic field generated at a distance of 1 mm from the wire is about 10-4 Tesla, which is about 3 orders of magnitude smaller than the strength of a general permanent magnet. A strong permanent magnet that has little effect on the original magnetic field.

The influence of the magnetic field generated by the current on the original magnetic field is related to the measurement position, the shape of the magnet, the original magnetization direction, and the current loading direction.

Generally speaking, at a certain magnetic field strength measurement point, if the circular magnetic field generated by the current has the same magnetization direction as the original magnetic field, the magnetic field strength increases after superposition, which may change the direction of the magnetic field and increase the original magnetic field (when the permanent magnet is not fully magnetization); if the directions are not aligned, the magnetic field strength will weaken. In addition, the application of current causes a temperature increase, which may demagnetize the permanent magnets.

If alternating current is applied, eddy currents will be generated in the permanent magnet due to the generation of the alternating magnetic field. For example, in a NdFeB permanent magnets synchronous motor, the eddy current loss of a permanent magnet synchronous rotor with a diameter of 100mm is generally 10-2 to 102W. Due to the high conductivity and large temperature coefficient of neodymium magnets, it is easy to cause the performance of the motor to decline due to the increase in temperature, and even the danger of demagnetization. In addition, phenomena such as electromagnetic damping and skin effect exist in some applications.

We have been engaged in the production of rare earth neodymium magnets for more than 10 years. After years of development in the field of rare earth permanent magnets, we not only produce the highest grade NdFeB power magnets, but also various magnet components (such as holding magnets, pot magnets, separation magnets, and other magnet magnetic tools). If necessary, welcome to consult.