Industrial seals play a critical role in maintaining the integrity and functionality of various equipment and systems, ensuring smooth operations in a wide range of industries. From preventing leaks to reducing friction, the right sealing solution is essential for optimal performance. In recent years, the use of rectangle NdFeB magnets has emerged as a game-changer in the field of magnetic sealing systems. In this blog post, we will explore the benefits and applications of these powerful magnets in industrial seals.

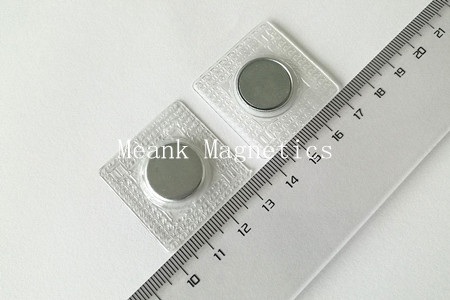

Rectangle NdFeB magnets, also known as neodymium magnets, are some of the strongest permanent magnets available today. These magnets owe their impressive magnetic properties to the combination of neodymium, iron, and boron elements. With their high magnetic energy product, rectangle NdFeB magnets offer superior holding force and excellent resistance to demagnetization. These attributes make them an ideal choice for a variety of industrial applications, including sealing solutions.

When it comes to industrial seals, maintaining a reliable and efficient sealing mechanism is crucial. Rectangle NdFeB magnets can enhance sealing solutions by providing magnetic pressure, sealing force, and a stable contact surface. Whether used in gaskets, O-rings, or other seal designs, these magnets can improve the overall performance and longevity of sealing systems. The strong magnetic force of rectangle NdFeB magnets ensures a secure and tight seal, even under extreme conditions.

Rectangle NdFeB magnets find applications in a wide range of industries, where seals play a critical role in preventing leaks or reducing friction. In the automotive industry, these magnets are used in engine gaskets to create a tight seal and maintain optimum engine performance. Similarly, in the aerospace industry, rectangle NdFeB magnets are utilized in seals for fuel systems to prevent fuel leakage. Furthermore, these magnets are also common in industrial machinery, medical equipment, and electrical devices, where an effective sealing solution is essential.

The use of rectangle NdFeB magnets in industrial seals offers several advantages over traditional sealing methods. Firstly, their strong magnetic force provides a reliable sealing mechanism, ensuring minimal leakage and improved efficiency. Additionally, these magnets are compact and lightweight, making them easy to integrate into existing seal designs without compromising overall equipment performance. Moreover, rectangle NdFeB magnets have a long service life and are highly resistant to corrosion, making them a cost-effective choice in sealing applications.

In conclusion, rectangle NdFeB magnets have revolutionized the field of magnetic sealing solutions. Their remarkable magnetic properties, combined with their versatility and durability, make them an ideal choice for industrial seals. From automotive to aerospace applications, these powerful magnets deliver enhanced sealing performance, reducing the risk of leaks and optimizing system efficiency. By incorporating rectangle NdFeB magnets into sealing designs, industries can benefit from improved reliability, cost-effectiveness, and long-lasting sealing solutions.