The

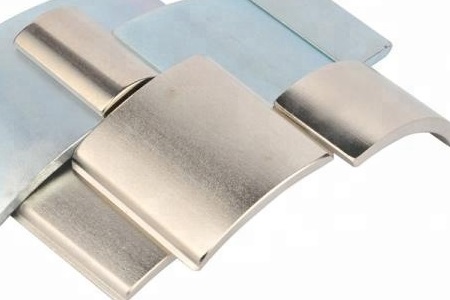

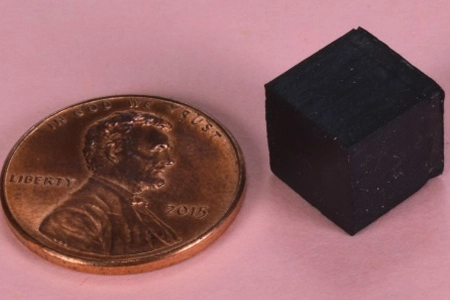

neodymium magnet was invented in 1982 by Sakawa Masahito and others of the Sumitomo Special Metal Corp. It is known by its chemical formula that it is mainly composed of chemical elements such as neodymium, Ferrum and boron. The neodymium magnets can be divided into bonded neodymium and sintered neodymium. Bonding is actually injection molding, and sintering is vacuum pumping through high temperature heating molding. The material brand is N35-N52. Various shapes can be processed according to specific requirements, such as circle, square, perforation, magnetic tile, magnetic rod, convex, trapezoid, etc. Although these advantages, the surface is easy to rust. It is usually required for some protective surface treatment, such as nickel plating, galvanizing, gold plating, epoxy resin and so on. The working temperature of Nd-Fe-B magnet is below 80 degrees, but there are several kinds that can work in 200 degrees. It is mainly used in electronics, electrical appliances, packaging, electrical machinery, toys, leather goods and automobile machinery, etc.

Neodymium magnets are the most commercialized magnets by far, which are known as the king of magneto. It has the highest magnetic properties that can make its BHmax over 10 times than Ferrite. Its own mechanical processing performance is also quite good. The working temperature is up to 200 degrees Celsius. Moreover, its texture is hard, its performance is stable, and its cost performance is high. Its application is extremely extensive. But due to its strong chemical activity, the surface layer must be treated. (such as Zn plated, Ni plated, electrophoretic, passivation, etc.).