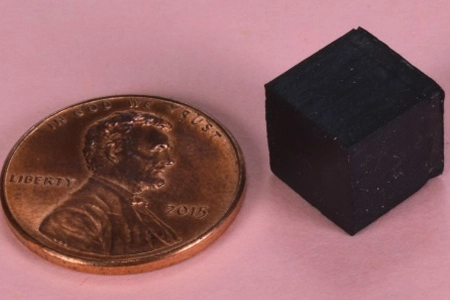

SmCo magnet is a rare earth magnet, which is made from samarium, cobalt and other rare earth metal materials to melt alloy, it is a magnetic tool material made by crushing, pressing and sintering, having a high magnetic energy product and a very low temperature coefficient,its maximum working temperature can up to 350 ℃, the negative temperature is unlimited. The maximum magnetic energy product (BHmax), coercivity (coercivity), temperature stability and chemical stability of Nd-Fe-B permanent magnet are higher than those of Nd-Fe-B permanent magnet at operating temperature above 180 ℃. It has strong corrosion resistance and oxidation resistance; so it is widely used in aerospace, national defense military industry, microwave device, communication, medical equipment, instrument, all kinds of magnetic transmission device, sensor, magnetic processor, motor, magnetic crane and so on. The maximum magnetic energy product (BHmax) of

SmCo magnets ranges from 16 MGOe to 32 MGOe, the theoretical limit is 34 MGOe.

SmCo magnets have two composition ratios, 1:5 (samarium atom: cobalt atom) and 2: 17.

Process

SmCo magnets production process: Charge mixture→ Smelting ingot→ Powder process→ Profiling→ Sintering tempering → Magnetic testing → Grinding → Pin cutting processing →Finished product [3].

These alloys are usually machined in a nonmagnetized state. Fine wet grinding (water-cooled heat dissipation) and diamond grinding wheels for SmCo. Grinding waste must not be completely dry because SmCo has a low ignition point. A small spark, such as production with static electricity, can be burned lightly.The temperature of the fire is very high and difficult to control.