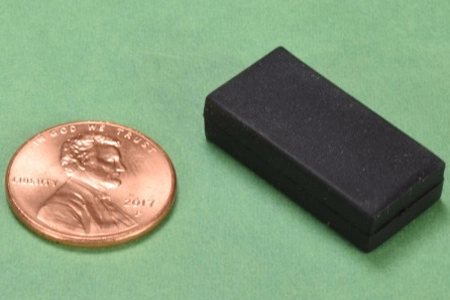

Samarium cobalt magnets (SmCo) are a type of rare-earth magnet made from an alloy of samarium and cobalt. Renowned for their high magnetic strength, they can produce a strong magnetic field even in small sizes. These magnets are resistant to demagnetization and perform well in extreme temperatures, ranging from -60°C to +300°C, making them ideal for high-performance applications in industries like aerospace, medical, and automotive. Samarium cobalt magnets also exhibit excellent corrosion resistance, making them durable in harsh environments. Although more expensive than other magnets, their superior performance in demanding conditions justifies their use in precision equipment and specialized technologies.

Neodymium magnets, also known as NdFeB magnets, are primarily made from an alloy of neodymium (Nd), iron (Fe), and boron (B). The combination of these elements creates a powerful magnetic material with a high energy product, giving neodymium magnets their strong magnetic field. Small amounts of other elements like dysprosium or praseodymium are sometimes added to improve performance, particularly in high-temperature environments.

Samarium cobalt (SmCo) magnets and neodymium (NdFeB) magnets are both powerful rare-earth magnets, but they have key differences in strength, performance, and applications.

Samarium cobalt magnets are also strong, they usually have a lower energy product compared to neodymium magnets. However, they still provide excellent magnetic strength for smaller sizes. While Neodymium magnets are typically stronger than samarium cobalt magnets. They have a higher energy product (measured in MGOe), meaning they can generate a stronger magnetic field relative to their size. This makes neodymium magnets ideal for applications that require compact, high-power magnets.

One of the key advantages of samarium cobalt magnets is their superior temperature stability. They can withstand temperatures up to 300°C without significant loss of magnetic properties, making them suitable for applications in extreme heat. Neodymium magnets are sensitive to high temperatures and can lose their magnetism if exposed to temperatures above 80-150°C, depending on the specific grade. This limits their use in high-temperature environments without additional protective coatings.

Samarium cobalt magnets have excellent natural corrosion resistance. Unlike neodymium magnets, they can withstand harsh environmental conditions without the need for additional coatings, making them ideal for use in corrosive or outdoor settings. But neodymium magnets are highly susceptible to corrosion, especially if not properly coated (typically with nickel or epoxy). In environments with high humidity or exposure to moisture, they may degrade over time.

Samarium cobalt magnets are more expensive due to the rarer materials involved in their production. The higher price point is often justified by their enhanced temperature and corrosion resistance, especially for specialized industries. In contrast, neodymium magnets are generally less expensive than samarium cobalt magnets. Their lower cost is due to the more abundant materials used (neodymium and iron), making them a more cost-effective solution for many applications, especially where extreme strength is required in a smaller package.

Samarium cobalt magnets are more durable and maintain their magnetic properties over a longer period, even in harsh or extreme environments. Their stability and resistance to demagnetization ensure they provide long-lasting performance, especially in demanding applications. While neodymium magnets are incredibly strong, they can lose their magnetism over time if exposed to high temperatures or corrosive environments. This can lead to a decrease in performance in long-term applications.

| Feature | Samarium Cobalt (SmCo) | Neodymium (NdFeB) |

| Magnetic Strength | Strong, but lower energy product compared to NdFeB | Strongest commercially available, higher energy product |

| Temperature Stability | Excellent (up to 300°C) | Lower (80-150°C, depending on grade) |

| Corrosion Resistance | Excellent (natural) | Poor (susceptible to corrosion) |

| Cost | Higher | Lower |

| Durability/Longevity | Excellent | Good, but can degrade with heat/corrosion |

Choosing between samarium cobalt (SmCo) and neodymium (NdFeB) magnets depends on the specific needs of your application. If you require the strongest possible magnetic field in a compact size and cost is a major consideration, neodymium magnets are the better choice due to their higher magnetic strength and lower cost. However, if your application involves high temperatures, corrosive environments, or long-term durability, samarium cobalt magnets are preferable. They offer superior temperature stability, resistance to demagnetization, and natural corrosion resistance, making them ideal for demanding or harsh conditions, even though they tend to be more expensive.