1. Coreless Nd-Fe-B permanent magnet motor

Use excellent properties of Nd-Fe-B permanent magnetic materials with high coercivity without or less use silicon steel sheet to make coreless motor , the weight greatly reduced. Coreless permanent magnet motor using magnetic structure and cosine magnetization, the magnetic field generated by a sinusoidal distribution, so it can not chute can be used for concentrated winding AC control.The winding end is short, the loss is small, the torque density is high, and the vibration and noise are reduced significantly. It is applied in many aspects, such as automobile steering wheel drive, robot, elevator and DVD drive.

2. Transverse flux Nd-Fe-B magnet motor

In order to solve the contradiction between the tooth width of the coil placing groove and the flux flows through the width, improve the motor power and torque density, people continue to explore new magnetic circuit structure, the transverse flux motor (Transverse Flux Machine) structure thought. The motor stator slot structure and armature coil perpendicular to each other. The main motor flux along the axial flow of current and magnetic load there is no competition in the space, thus the stator coils size and size are independent of each other, in a certain range can be chosen arbitrarily, and improve the power density. The structure of such motor R & D has just started, and has broad prospects for development.

3. Permanent magnet special motor

There are many kinds of control motors and special motors. One of the common trends is permanent magnetization, which replaces electric excitation with high performance permanent magnet excitation.

Because of the rare earth

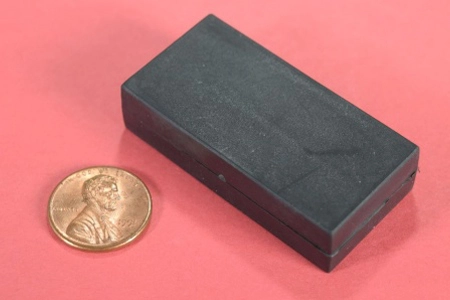

permanent magnet with high remanent flux density, high coercivity, and high energy product, the motor can be made with the air gap length and gap density, and the permanent magnet is very flexible and placed on the magnetic circuit structure design, can use the occasion, especially the needs for cars, computers and aerospace engineering, structure made of different shapes and sizes with the traditional motor, such as motor, slotless motor. It can further reduce the motor mass and moment of inertia, improve the response sensitivity of the motor;