Imagine a magnet so powerful it can pull through walls, levitate objects, and revolutionize technology. This isn't science fiction; it's the reality of neodymium magnets, the strongest permanent magnets readily available. But beyond their impressive strength, these versatile mini-marvels are transforming industries and igniting creative possibilities. Let's delve into the world of neodymium magnets, exploring their composition, safety considerations, and diverse applications.

A neodymium magnet is a powerful type of permanent magnet made from a combination of neodymium, iron, and boron alloy, known as NdFeB. Renowned for its exceptional strength, neodymium magnets are the strongest type of permanent magnets commercially available. They possess high coercivity, meaning they are resistant to demagnetization, and high remanence, allowing them to maintain their magnetization even in the absence of an external magnetic field.

Neodymium magnets are primarily composed of an alloy called NdFeB, which stands for neodymium, iron, and boron. This combination is responsible for their exceptional strength and magnetic properties.

However, NdFeB isn't the whole story. In smaller quantities, you may also find elements like:

Praseodymium(Pr): Often added to refine the crystal structure and improve magnetic performance.

Dysprosium(Dy): Enhances high-temperature stability but can be expensive and limited in availability.

Aluminum (Al): Improves corrosion resistance and machinability.

Niobium (Nb): Strengthens the magnet and helps prevent grain growth.

The specific composition of a neodymium magnet depends on its intended application and desired properties. Manufacturers carefully balance the proportions of these elements to achieve the optimal strength, temperature resistance, and cost-effectiveness for each individual use case.

Neodymium magnets are generally safe to handle, but they can pose risks if mishandled or ingested. Some considerations regarding the safety of neodymium magnets include:

Choking Hazard: Neodymium magnets are small and extremely powerful, posing a choking hazard if swallowed. If multiple magnets are ingested, they can attract to each other through intestinal walls, causing serious health complications. Therefore, neodymium magnets should be kept away from small children and pets who may accidentally swallow them.

Pinching and Crushing: Neodymium magnets are strong enough to cause pinching or crushing injuries if fingers or other body parts get caught between them. Care should be taken when handling large or powerful neodymium magnets to avoid injury.

Skin Irritation: Some people may experience skin irritation or allergic reactions when in direct contact with neodymium magnets. This can occur due to the nickel coating often applied to the magnets to protect against corrosion. It is advisable to handle neodymium magnets with gloves or avoid prolonged skin contact if sensitive to nickel.

Electrical Interference: Neodymium magnets, like NdFeB rectangular magnets, can interfere with electronic devices and equipment, including pacemakers, credit cards, and electronic devices such as laptops and cell phones. Individuals with medical implants or sensitive electronic devices should avoid prolonged exposure to neodymium magnets.

Overall, while neodymium magnets are safe for most uses when handled responsibly, it is essential to be aware of potential hazards and take appropriate precautions to prevent accidents or injuries.

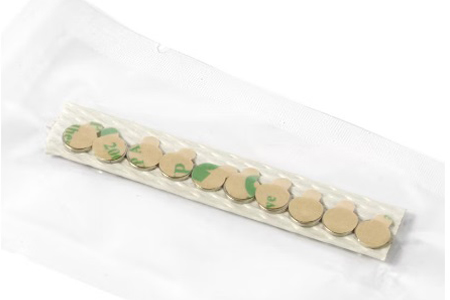

Neodymium magnets, such as neodymium cylinder magnets for sale, are the strongest permanent magnets commercially available. This unique property, coupled with their small size and lightweight nature, makes them incredibly versatile and widely used across various industries. Here's a breakdown of their applications with more details:

Electronics

Hard Disk Drives: The tiny magnets in hard drives spin platters, storing and retrieving data efficiently.

Loudspeakers: Neodymium magnets power the voice coils in speakers, producing clear and powerful sound.

Electric Motors: These magnets are used in motors for various applications, including drones, power tools, and electric vehicles, due to their high efficiency and compact size.

Sensors and Actuators: They are used in various sensors and actuators for precise positioning, motion detection, and feedback mechanisms in devices like smartphones and robotics.

Medical Technology

MRI Machines: Powerful neodymium magnets create the strong magnetic field needed for detailed medical imaging in MRI machines.

Pacemakers and Defibrillators: Tiny magnets are used in these devices to ensure accurate positioning and function within the body.

Surgical Instruments: Magnetic laparoscopic tools utilize neodymium magnets for minimally invasive surgery with improved dexterity and control.

Dental Implants: These magnets can be used in certain dental implant designs for improved retention and stability.

Industrial Applications

Electric Vehicles: Neodymium magnets are crucial components in electric vehicle motors, contributing to their efficiency and range.

Wind Turbines: The generators in wind turbines rely on neodymium magnets to convert wind energy into electricity.

Separation and Sorting: Magnetic separators utilize their strong attraction to separate and sort different materials based on their magnetic properties.

Data Storage: High-performance data storage devices like solid-state drives (SSDs) can utilize neodymium magnets for faster access and data transfer.

Neodymium magnets are a testament to the power of miniaturization and innovation. Their exceptional strength and versatility have opened doors across industries, from powering everyday devices to driving medical advancements. As we continue to explore their potential, these mighty mini-magnets promise to shape the future in exciting ways.