Rubber magnets can be divided into isotropic rubber magnets and anisotropic rubber magnets, the latter having better magnetic properties. On this basis, it can be divided into single-sided magnetic rubber magnet and double-sided magnetic rubber magnet. Also, there are sticky and non sticky rubber magnets.

Magnetic rubber sheet, also known as rubber soft magnetic, is made by adding magnetic powder and various compounding agents through densification, calendering vulcanization and shrinkage vulcanization.

Magnetic rubber sheets can be made magnetic on one and two sides and can be painted with UV bright (matte) varnish. The main physical properties of magnetic rubber sheets are high specific gravity.

Due to the large amount of magnetic powder, the specific gravity reaches 3.8cm3/g, which is a relatively large proportion of the film. The hardness is about 85 degrees, and the magnetism is about 550-750 Gauss. Has good flatness and brightness. In addition, it has good abrasion resistance and high pressure resistance. There are black, dark brown, white and other colors to choose from, the thickness is 0.3-10mm, the width is 5-600mm, and the length can be cut or rolled according to actual needs.

Magnetic rubber sheet products mainly include rubber magnetic sheets, extruded magnetic strips, refrigerator magnets, etc., which can be made into coils, tapes and other shapes and specifications according to customer requirements. It can be decorated with PVC, double-sided tape, imported 3M glue, four-color printing, etc., and supports single-sided and double-sided multi-pole magnetization. Magnetic plastic sheets are widely used in door and window seals, toy industry, advertising industry, vehicle equipment, refrigerator magnets, auto repair shops and other occasions.

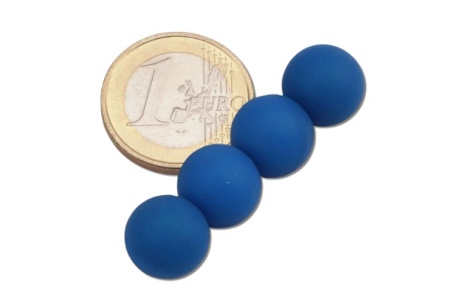

Rubber magnets are composed of magnetic powder, chlorinated polyethylene and other food additives, which are extruded and rolled. Rubber magnets can be isotropic and anisotropic, and can be bent, twisted and curled. It can be used without further mechanical production methods and can be shaped to the required material size. It can also be coated with PVC, adhesive and UV varnish according to customer requirements. Its magnetic energy product is 0.60 to 1.50 MGOe.

Production process: batching→mixing→extrusion/calendering/injection→processing→magnetization→inspection→packaging.

The application fields of rubber magnets are refrigerators, information desks, advertisements, fasteners that fix objects on metal bodies, toys, teaching instruments, switches and sensors, etc. Mainly used in micro motors, refrigerators, disinfection cabinets, kitchen cabinets, toys, stationery, advertising and other industries.

MEANK has been engaged in the production of rare earth neodymium magnets for more than 10 years. After years of development in the field of rare earth permanent magnets, we not only produce the highest grade NdFeB power magnets, but also various magnet components (such as holding magnets, pot magnets, separation magnets, etc.). If necessary, welcome to consult.