Ceramic magnet is a kind of permanent magnet, which is not easy to corrode and demagnetize. The production technology is simple and the price is low. Compared with other permanent magnets, strong ceramic magnets are hard and brittle with low magnetic energy. But because of the simple production technology and low price, ceramic magnets have the highest output in the entire magnet industry and are widely used in industrial production. The raw materials of ceramic magnets are SrO or BaO and Fe2O3. So why don't ceramic magnets rust? What are their advantages?

The chemical name of ceramic magnets is ferroferric oxide with main component Fe3O4. They are already iron oxides, so it's hard for them to be oxidized again. The main component of other magnets is iron, which is made of magnetized metallic iron or other elements. Like other iron and steel, they can be oxidized and rusted, and the oxidized part will lose magnetism.

1. Since the cost of raw materials is very low, the cost of strong ceramic magnets is low, and the price is also very low.

2. The strong ceramic magnets will not rust.

3. Good temperature stability. They can be used at -40 degrees Celsius and 350 degrees Celsius.

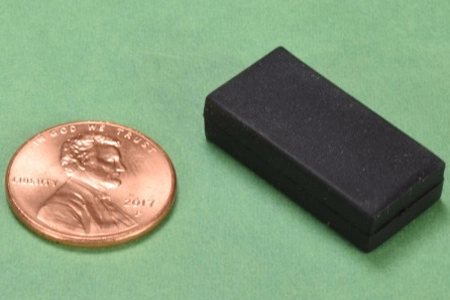

4. Strong ceramic magnets are light in weight.

5. The constants of magnetic crystals are large.

6. The demagnetization curve is approximately a straight line.

Ferrite is widely used, and the amount is very large. It does not rust, oxidize, or corrode, and it is absolutely environmentally friendly. All above are the advantages of strong ceramic magnets. We hope that this article is helpful to you.